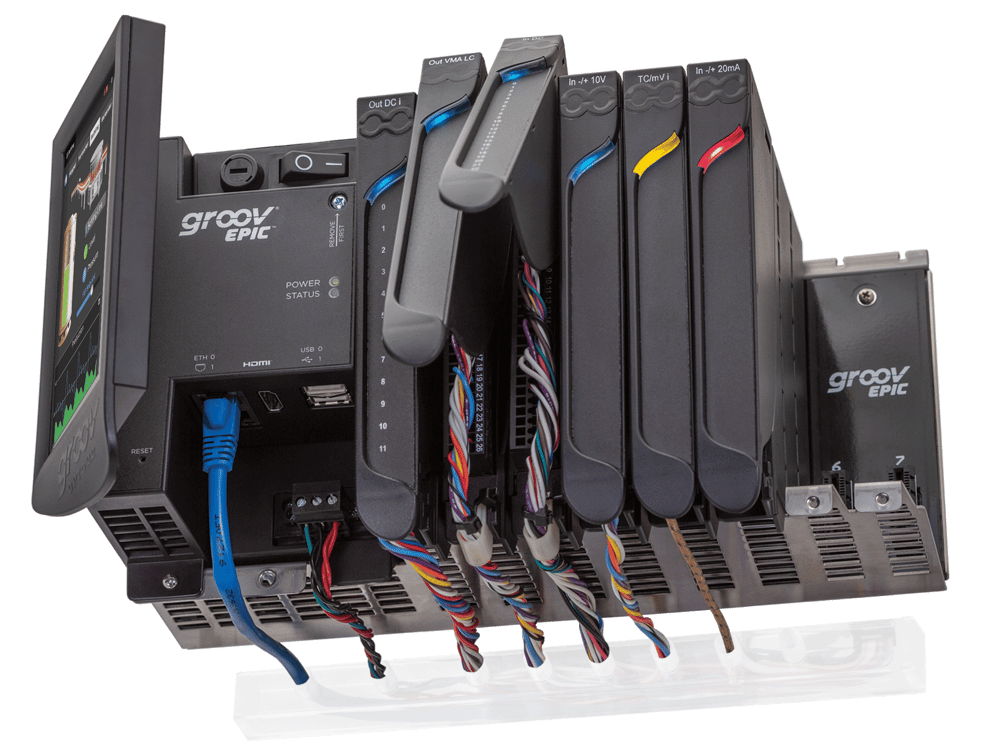

This is EPIC! It's the groov EPIC System

Your best choice for any industrial internet of things (IIoT) or automation application

groov EPIC® gives you guaranteed-for-life I/O, a flexible Linux®-based controller with gateway functions, high-resolution touchscreen, two independent network interfaces, USB and HDMI ports, and software including control programming, groov View for device-independent HMI, Node-RED for simple data flows, and Ignition Edge® for OPC-UA drivers and MQTT/Sparkplug communications—and more.

Watch the groov EPIC webinar for details on hardware & software, problem-solving scenarios, and product demos:

"We got groov EPIC up and running in less than a day. Now when an alarm occurs, the guys get a text or email on their phones. They check out the live status remotely and make an informed decision to come in or not, saving time, money and hassle." - Gregg Martin, President, GMI Instrumentation

Here are some of the EPIC features you'll like.

If you spec or buy systems:

- UL Hazardous Locations approved and ATEX compliant

- Wide -20 to 70 °C operating temperature range

- Stainless-steel chassis with 4, 8, or 16 I/O modules

- I/O module density of up to 24 channels per module

- Multi-featured analog output with voltage, current, and loop sourcing in single module

- Analog input resolution of 20 bits at 0.1% accuracy over span

- DC outputs with load switching at 0.4 A per channel @ 70 ºC

- AC outputs with load switching at 0.5 A per channel @ 70 ºC; blown-fuse detection

- AC/DC mechanical relay output at 5 A per channel @ 70 ºC

- Channel-to-channel isolation available

- Multiple power supply options including AC, DC, and pass-through

- Dual, independent Gigabit Ethernet network interfaces

- Fully compatible with the SNAP PAC System

- All products made in the U.S.A.

If you install, commission, or use systems in the field:

- Integrated high-resolution color touchscreen for commissioning and HMI

- No PC required for I/O and network configuration or troubleshooting

- Touch-sensitive pad on I/O modules for configuring and testing

- Viewable I/O module specs and wiring diagrams

- Stainless-steel DIN rail or panel mounted chassis

- Compact footprint with integrated power supply

- Spring-clamp terminal strip directly atop I/O module accommodating up to 14 AWG wire

- Integrated wireway with two-position swing-away cover

- Single module retention screw and strain relief tab built in

- LED indicators for module health at a glance, and for individual discrete channels

- Hot-swappable I/O

If you're a developer:

- Securely shares data among databases, cloud services, PLC systems, and more

- Real-time, open-source Linux OS

- Flowchart-based PAC Control with scripting for control programming

- Future support for IEC 61131

- Optional secure shell access (SSH) for your own custom-developed application

- groov View for building and securely viewing operator interfaces from any authorized mobile device or PC with a web browser—and from the EPIC controller's touchscreen

- Open-source Node-RED for wiring together APIs, cloud applications, and databases with simple data flows, using pre-built nodes

- Ignition Edge (a product of Inductive Automation®) with OPC-UA drivers to Allen-Bradley® and Siemens® PLC systems

- MQTT transport protocol with Sparkplug payload for efficient data communications

- RESTful API to groov EPIC controller

If you're an OEM:

- Remote configuration, troubleshooting, and system visualization from any web browser on any authorized device

- Integrated high-resolution color touchscreen with HDMI output for optional external monitor

- groov View HMI viewable on touchscreen, external monitor, and browser-based devices

- Dual, independent Gigabit Ethernet network interfaces

- Dual USB ports for serial communications or touchscreen monitors

- Real-time, open-source Linux OS running on an industrial quad-core ARM® processor

- 2 GB RAM, 6 GB user space on industrial solid-state drive

.jpg?width=150&name=blog.opto22.comhubfsControlEngAward2019%20(002).jpg)